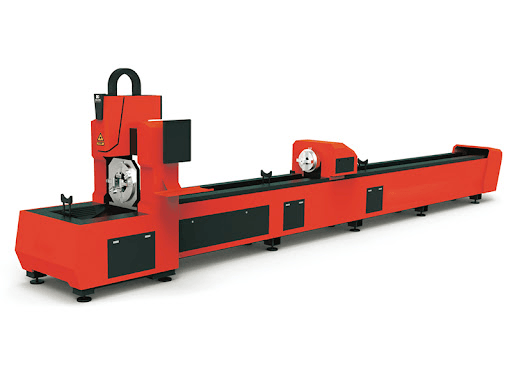

The intersecting wire EDM is a high-precision CNC machine. It cuts complex three-dimensional curves at pipe intersections. By automating tasks like patterning, cutting, and polishing, it eliminates the need for manual labor. This significantly increases efficiency and accuracy. Industries such as steel structures, petrochemicals, marine engineering, and pressure vessels rely on this technology. It plays a key role in high-end manufacturing.

How the Intersecting Wire EDM Operates

At its core, the intersecting wire EDM uses a multi-axis linkage system. This system typically has five to eight axes. A CNC system controls these axes through specialized software. Operators input parameters like pipe diameter, wall thickness, intersection angle, and groove requirements. The software then calculates and generates the precise cutting path. The machine uses a high-performance servo motor and precision rack-and-pinion drive system. It ensures positioning accuracy of ±0.2 mm and cutting length tolerance of ±1.5 mm. The machine meets international standards, including ISO 9013-2002. It supports various cutting methods, including flame cutting, plasma cutting, and laser cutting. The torch can oscillate up to ±60°, which enables it to handle various beveling needs.

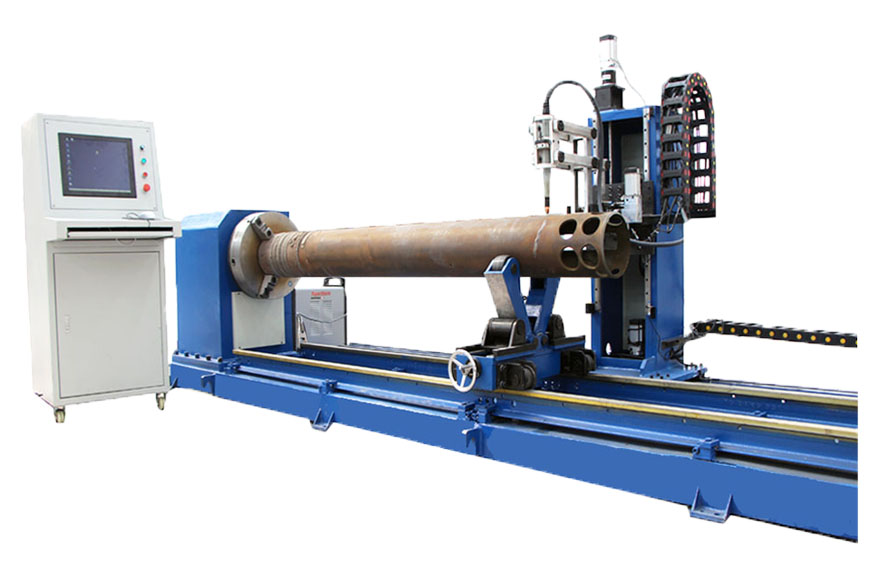

Applications of the Intersecting Wire EDM

The intersecting wire EDM is both efficient and versatile. It processes materials such as carbon steel, stainless steel, aluminum alloys, and copper. It has a maximum load capacity of up to 10 tons. This makes it indispensable in many industries. For example, in building steel structures, it cuts pipe intersections in trusses and lattice shell structures. It ensures strong and reliable connections. In the energy and chemical sectors, it manufactures special-shaped and multi-way pipe fittings. These are used in oil pipelines, pressure vessels, and heat exchangers. The machine meets the demands of high-pressure and corrosive environments. In shipbuilding and offshore engineering, it creates piping systems and components for offshore platforms. In heavy machinery, it cuts hydraulic pipelines and structural frames. It also plays a key role in emerging sectors like amusement facilities and lighting design. It rapidly prototypes custom-shaped metal fittings.

With intelligent nesting software, the intersecting wire EDM maximizes material usage. It reduces waste and improves production efficiency. This ensures precise manufacturing while optimizing cost-effectiveness.

Welcome to Order

Ready to enhance your manufacturing capabilities with the latest intersecting wire EDM technology? Contact us today. Let us help you meet your specific production needs. We offer customized solutions that improve both quality and efficiency.