The metal pipe cutting industry is undergoing significant changes. These changes are driven by the transformation toward intelligent manufacturing. Modern machines have evolved from basic mechanical devices into high-precision automated systems. These systems now meet the growing needs of industries such as petroleum, metallurgy, and automotive manufacturing. As a result, innovations in this field improve efficiency, accuracy, and productivity across multiple sectors.

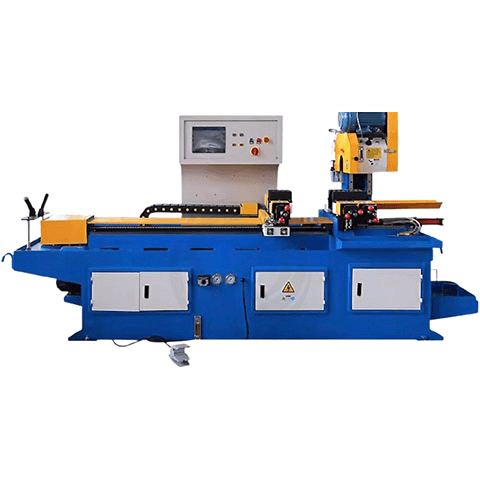

Automated Pipe Cutting Machines

Automated pipe cutting machines are essential in modern processing workflows. These include both semi-automatic and fully automatic models. Semi-automatic models use pneumatic operation to provide automatic clamping and blade feed. This allows them to cut round pipes up to 90mm at 90° and 70mm at 45°. Therefore, they offer a reliable and efficient alternative to traditional abrasive cutters.

Fully automatic models are designed for high-precision cut-to-length operations. These machines feature servo motor systems, PLC numerical control, and touchscreen interfaces. The integration of these technologies ensures seamless automation. As a result, they enable continuous and precise cutting of varying pipe sizes, offering high consistency and accuracy throughout production.

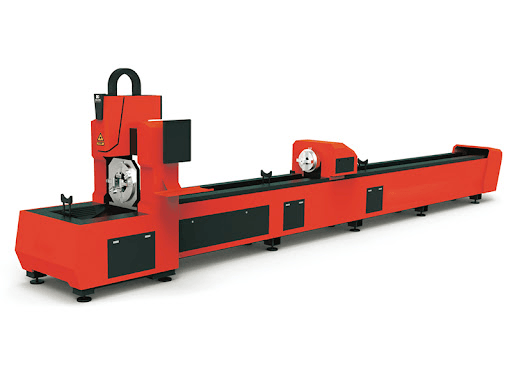

Laser Tube Cutting Machines

Laser tube cutting machines combine CNC technology with laser cutting. They produce highly accurate cuts using light energy. Fiber lasers with power levels exceeding 3000W vaporize metal instantly. This results in clean, precise cutting seams. These machines also offer exceptional precision (±0.05mm). They can cut a wide range of materials, including carbon steel, stainless steel, and aluminum alloys.

Laser tube cutting machines can also perform intricate cuts. These include complex patterns and 3D bevels. As a result, they are indispensable for high-end manufacturing processes that require both versatility and precision.

Precision Pipe Cutting Machines

Precision pipe cutting machines, such as planetary and CNC models, deliver exceptional accuracy and reliability. Planetary machines use cold cutting technology. This technology eliminates the risks of deformation and contamination during the cutting process. The cutting head rotates around the stationary pipe. This ensures burr-free, vertical cuts and completes weld bevels in a single operation.

CNC pipe cutting machines use digital control systems to perform precise cuts. These machines are available in three- or five-axis configurations. They can cut fixed or variable-angle holes and lines. As a result, they offer exceptional flexibility and precision, making them ideal for complex applications.

Why Choose Us

At Jiuying, we offer state-of-the-art metal pipe cutting machines. These machines deliver exceptional precision, efficiency, and reliability. Whether you need semi-automatic, fully automated, or advanced laser and CNC systems, our equipment is designed to meet your specific needs. We pride ourselves on offering outstanding customer support. Additionally, we maintain a strong commitment to quality. This ensures that your operations run smoothly and efficiently at every stage.