blog

Exploring Cantilever Water Jet Cutting Machines

Share:

Facebook

Twitter

Pinterest

LinkedIn

Contact Us

Contact: Mr Liu

Whatsapp/Mob/Wechat:008613394110095

Email:liu@weldcnc.com

Most Popular

Get The Latest Updates

Subscribe To Our Weekly Newsletter

No spam, notifications only about new products, updates.

Product Catalog

Request a Quote

Ready to Work Together? Build a project with us!

Learn More From

Frequently Asked Questions

Please tell us what you want to mark, the size and desired power and other information.

Yes, we will, English manual and video will come along with the machine.You also can contact our service team if you need any help during use our machines.

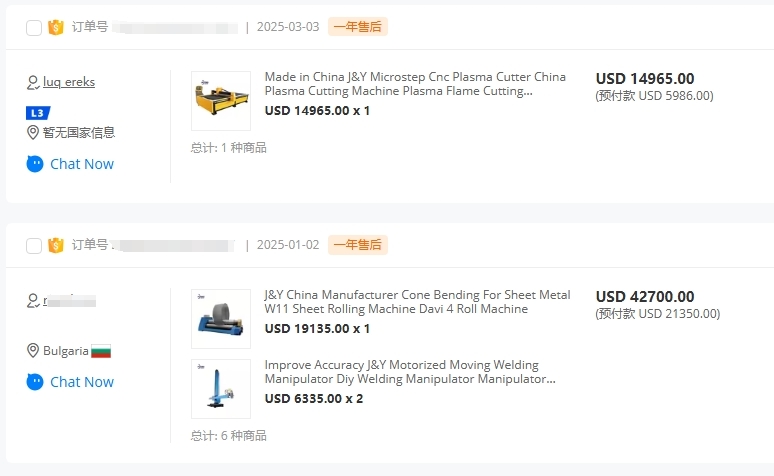

Delivery time is 20-30 days after receiving the deposit

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

Read More