Desktop CNC plasma cutting machine: An Overview

The Desktop CNC Plasma/Flame Cutting Machine stands as a testament to innovation and technology. It brilliantly combines high speed, precision, and a compact desktop design, perfect for achieving intricate cuts on various materials.

General Description: Employing a user-friendly interface, this machine offers ease of installation, simple operations, minimal inertia, and a stable operational experience. It’s particularly adept at automatically cutting medium and thin non-ferrous metal plates, stainless steel, and carbon steel plates. Based on customer requirements, it can be designed as either a smoking table or an underwater cutting table, ensuring a tailored fit for manufacturing needs.

Its utility is diverse, finding applications in numerous sectors such as sheet metal processing, aerospace, electronics, appliances, food machinery, engineering machinery, precision parts, metallurgical equipment, elevators, crafts, tool processing, decoration, advertising, and a plethora of other manufacturing industries.

Key Features:

- Robust Construction: The machine is constructed with a steel structure, welded to perfection. It undergoes overall tempering to eliminate welding stresses, ensuring a performance that is stable and reliable. Accompanied by an independent system control cabinet, it offers high automation levels, ease of operation, and easy maintenance.

- Unique Environment-friendly Design: This machine is fitted with a distinctive smoke and dust removal device. Additionally, it boasts an exhaust cutting table and a slag storage device, promoting a cleaner working environment.

- Advanced CNC System: The CNC ion/flame cutting system can intricately cut any plane shape, comprising both straight lines and arcs. Graphics are displayed dynamically and statically, making it intuitive and easy to grasp. You can either program directly on the machine or use a computer. Moreover, CAD files can be converted to G code files and transferred via a U disk for automatic cutting.

- Versatility: This equipment is used across multiple sectors like automobile manufacturing, marine production, ventilation, kitchen cabinets, steel structure processing, advertising cutting, engineering machinery, aerospace, decoration, and many more.

- Environmentally Considerate: The machine possesses a unique smoking dust removal feature, in addition to an exhaust cutting table and a slag storage device, which ensures a clean and safe working atmosphere.

- Precision Cutting: With a high-response sensitivity arc pressure height regulator, the machine automatically adjusts cutting distance, ensuring a flawless cut every time.

- Customizable Power Supply: Users can equip the machine with various plasma power supplies, tailored to the cutting needs of different metal materials.

In essence, the Desktop CNC Plasma Cutting Machine is a technological marvel, designed to cater to precision cutting needs across a multitude of industries, promising efficiency and reliability.

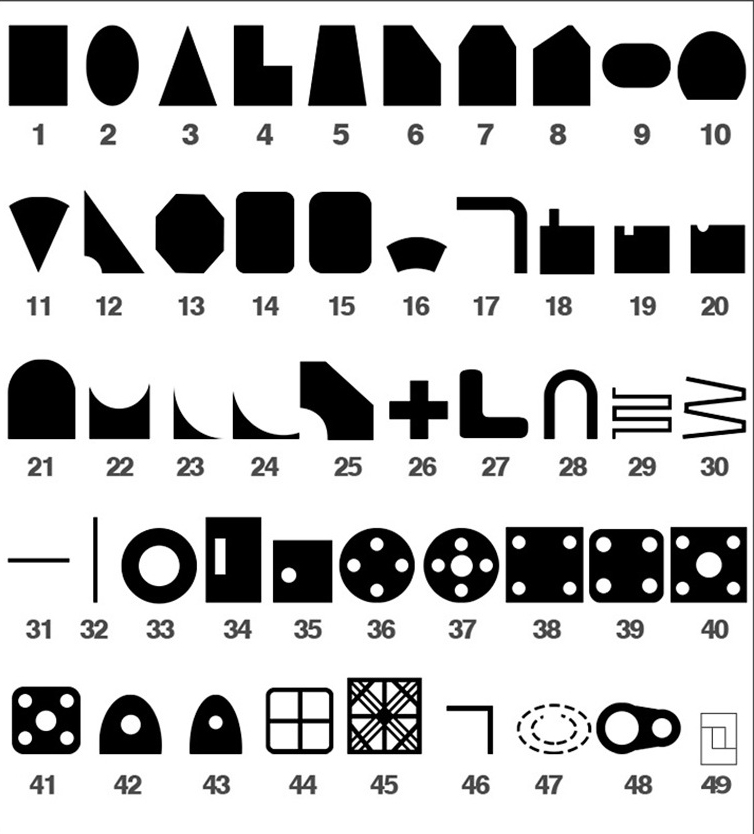

The system comes with 48 reference graphs

You can edit the size of each shape and the number of cuts you want to make

Cut sample display

Applied to, steel plate blanking, accurate cutting a variety of special-shaped workpiece and other cutting purposes

Desktop CNC plasma cutting machine detail display

Independent control cabinet

Easy to move, simple system operation, can realize a variety of graphics and text processing.

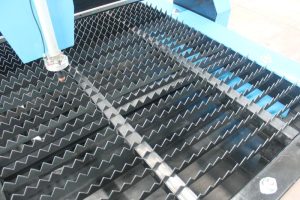

Cutting table

The workbench is equipped with a sink to reduce soot pollution. Surface serrated design, reduce the cutting process to the workbench damage.

Rigid design

After secondary aging treatment, fully eliminate the internal stress. The machine tool accuracy is stable for a long time to ensure the cutting accuracy.

Two-sided drive

Bilateral drive adopts symmetrical processing, stable center of gravity, to ensure a good dynamic balance.

Plasma power supply

Brand: Huayuan, Haibao and other brand power supply optional, stable performance, long service life.

Desktop CNC plasma/flame cutting machine product parameters

Desktop CNC plasma cutting machine model selection:

| Model | 1325 | 1530 | 2040 |

| Working size | 1300*2500mm | 1500*3000mm | 2000*4000mm |

| Adjustable Height of cutting torch | 100mm | ||

| Driving mode | Double side driving with marking head | ||

| Lifting station | One set for plasma cutting torch | ||

| Precision of rise and fall | ±0.2mm | ||

| Precision of line position | ±0.4mm/10m | ||

| Transmission system | X,Y Taiwan AMT high-precision,zero clearance increased linear guide+ rack | ||

| Z the arc voltage control | |||

| No-load travel speed | 15000mm/min | ||

| Working voltage | 3~ 220/50HZ | ||

| Control system | Beijing START plasma cutting system | ||

| Shanghai Fangling Plasma cutting system | |||

| Software support | Starcam, FASTCAM,AutoCAD | ||

| Instruction format | G code | ||

| Drive system | Stepper motor or Panasonic Servo motor | ||

| Plasma power | Chinese Huayuan brand plasma powers 40A to 400A | ||

| Power cutting thickness | 0.3mm to 30mm | ||

| plasma cutting parameters | |||

| huayuan power | Plasma Generator | Quality Cutting | Maximum Cutting |

| 63A | 8mm | 12mm | |

| 100A/120A | 18mm | 25mm | |

| 160A | 25mm | 35mm | |

| 200A | 30mm | 40mm | |

| hypertherm power | 45A | 5mm | 8mm |

| 65A | 8mm | 15mm | |

| 85A | 12mm | 20mm | |

| 105A | 15mm | 25mm | |

| 200A | 30mm | 40mm | |

| Note: cutting stainless steel is recommended on carbon steel standard basis, minus 3-5 mm, as standard | |||

If you’re looking to revolutionize your manufacturing process and want a machine that matches your ambitions, don’t hesitate to make an inquiry. We are here to guide and provide the best solutions tailored to your needs.contact us now!

Company Information

Dalian Jiuying Heavy Machine Co., Ltd. was established in 2015, focusing on sheet metal processing. At present, it mainly sells various metal cutting equipment, such as plasma cutting machine, laser cutting machine, water jet, etc. We have strong project design and product development capabilities, and can also provide customers with customized production services.

Cutting machines produced by Jiuying Heavy Machine Co., Ltd. are widely used all over the world with its advanced technology and high cost performance. Our customers are all over the world.Our international markets currently include the United States, Russia, the United Arab Emirates, the Philippines, Indonesia, Malaysia, Bangladesh, South Africa, etc.

Our company since its establishment, always adhere to the “customer first” principle, and will be unremitting spirit of innovation, leading professional technical strength, standard technology and standards, advanced manufacturing and testing technology and equipment, and continue to meet customer needs of production and manufacturing capacity.

Jiuying hopes to seek long-term win-win cooperation with you. Please choose us to work with you to create a better future!

Our Certificate