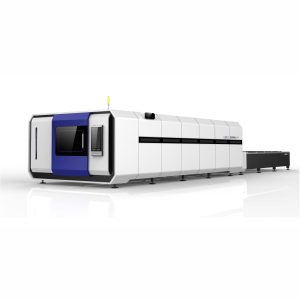

In today’s manufacturing era, the search is always on for multifunctional and efficient machinery. Enter the Tube Fiber Laser Cutting Machine—a groundbreaking innovation in the laser cutting field.

Features of the Tube Fiber Laser Cutting Machine:

- Dual Functionality:

- Plate Cutting:

- Precision: Achieve perfect and intricate cuts with a high degree of accuracy.

- Versatility: Whether you’re handling custom projects or mass production, this feature ensures that every plate cut meets stringent standards.

- Efficiency: Reduces the need for manual adjustments, speeding up the production process.

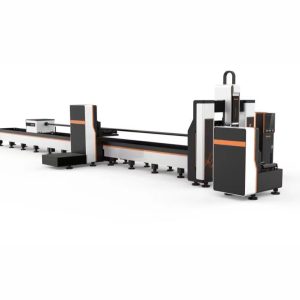

- Tube Cutting:

- Adaptability: Can handle both square and round tubes, making it suitable for a variety of industrial applications.

- Accuracy: Ensures clean, burr-free cuts, eliminating the need for post-processing in most cases.

- Quick Setup: Transitioning between plate and tube cutting is seamless, minimizing downtime.

- Plate Cutting:

- Power and Efficiency:

- IPG Sheet Metal Capabilities:

- Power Options: Users can choose between 1000W and 2000W, allowing for flexibility depending on the task’s requirements.

- Designed for 10mm Mild Steel: Specialized for a common industrial material, ensuring optimal cutting results and minimized waste.

- Speed: The high wattage ensures that cuts are not only precise but also quick, improving overall productivity.

- IPG Sheet Metal Capabilities:

- Cost-Effectiveness:

- Two-in-One Solution: By integrating the functions of two machines into one, businesses can save significant costs on equipment purchase, maintenance, and space.

- Long-Term Savings: Over time, the reduced need for repairs, lesser energy consumption, and efficiency can result in considerable financial savings.

- Independent Electric Control Cabinet:

- Jin Qiang 1530C Design:

- Sturdiness: Built to last, the cabinet is robust and designed to withstand the industrial environment.

- User-Friendly Interface: Operators can easily adjust settings, monitor operations, and troubleshoot if needed.

- Advanced Cooling Function:

- Efficient Cooling: The meticulously designed internal circuit system ensures that the machine’s temperature is always optimal, reducing wear and tear.

- Protection from Overheating: Overheating can cause significant damage. The cooling function guarantees the machine’s longevity and consistent performance.

- Air Conditioning Within the Cabinet:

- Reinforced Cooling: This feature ensures that the machine operates within a safe temperature range, even during extended operations.

- Prolonged Machine Life: By maintaining a consistent temperature, the machine’s components face less stress, ensuring a longer operational life.

- Jin Qiang 1530C Design:

These features collectively ensure that the Rotary Axis Laser Cutting Machine is not only a state-of-the-art piece of equipment but also a wise investment for businesses aiming for precision, efficiency, and cost-effectiveness in their operations.

Product Details – Tube Fiber Laser Cutting Machine:

1. Cast Iron Bed (Customized):

- Enhanced Stability: Utilizes flake graphite cast iron with a minimum tensile strength of 200MPa as the base material, ensuring maximum stability during operations.

- Sustained Precision: The use of graphite cast iron as the raw material ensures long-term precision that remains consistent for up to 50 years.

- Extended Service Life: Effectively reduces machining errors caused by bed vibrations, leading to cost savings for users.

2. Automatic Focusing Laser Head:

- German Precision: Features a German-imported Precitec laser head crafted from high-quality materials using advanced technology, guaranteeing strength and durability.

- Real-time Measurement: Capable of “online” measurements during production, providing accurate and rapid measurement results.

3. Fully Automatic Pneumatic Chuck:

- Efficient Clamping: Equipped with front and rear pneumatic chucks, offering a maximum clamping diameter of 350mm.

- Self-Centering Function: The chuck possesses a self-centering function, making pipe clamping more convenient and reducing manual centering errors.

4. Tube Pro (3000S) Cutting Software:

- Professional Cutting Software: Tailored for processing various types of pipes, it collects and processes real-time information to achieve high-precision cutting and optimize processing efficiency.

5. Material Savings:

- Optimized Chuck Structure: Features a redesigned pneumatic chuck structure with increased chuck claw capacity, providing more extensive clamping space.

- Reduced Material Waste: Residual material is minimized to less than 200mm, resulting in significant cost savings for users.

The Tube Fiber Laser Cutting Machine is designed with precision, durability, and efficiency in mind, ensuring that it meets the diverse needs of users in various industries while optimizing material usage.

Tube Fiber Laser Cutting Machine Product Paramenters

|

NO.

|

Item

|

Parameter

|

Unit

|

|

1

|

Cutting Size(L*H)

|

3000×1500

|

mm

|

|

2

|

X-axis travel

|

1550

|

mm

|

|

3

|

Y-axis travel

|

3050

|

mm

|

|

4

|

Z-axis travel

|

120

|

mm

|

|

5

|

X,Y positioning accuracy

|

±0.05/1000mm

|

mm

|

|

6

|

X,Y repeat positioning accuracy

|

mm±0.03/1000mm

|

mm

|

|

7

|

Acceleration

|

1G

|

m/s²

|

|

8

|

Max running speed

|

80

|

m/min

|

|

9

|

Maximum platform load

|

900

|

kg

|

|

10

|

Machine size (L* W *H )

|

4700×2200×1600

|

mm

|

|

11

|

Laser power

|

1kw-6kw

|

|

|

12

|

Control system

|

FSCUT2000C

|

w

|

|

13

|

Total power

|

20-40kw

|

|

|

14

|

Machine voltage

|

380v/50Hz

|

kw

|

Promotion 10% DISCOUNT IPG Sheet Metal 1000W 2000W plate and tube Laser Cutter Fiber Laser Cutting Machine for 10mm mild steel

A.Multifunction cutting for round, square, rectangle and oval pipes!

B. It can straight cut, angle cut, make holes, etc.

C. Smooth and burr-free cutting.

D. Cutting loss 0.1mm/cut only.

E. Excellent cutting accuracy ±1mm.

The Tube Fiber Laser Cutting Machine is adept at handling tubes ranging in length from 6m to 12m and capable of cutting diameters from 20mm up to 650mm. It’s versatile in managing materials like stainless steel, carbon steel, and aluminum tubes. Furthermore, this machine isn’t limited to traditional shapes; it’s designed to cut a variety of profiles, including round and square tubes, H and I beams, L shapes, angel steel, and even more complex shapes like oval.

Why Choose Our Tube Fiber Laser Cutting Machine?

- Precision: With the latest laser cutting technology, expect every cut to be detailed and accurate.

- Durability: The cooling system ensures that the machine has a prolonged life, promising a return on investment.

- Efficiency: With dual functionality, this machine saves time and reduces the need for space and additional machinery.

In a world where efficiency and precision are paramount, our Tube Fiber Laser Cutting Machine stands out. It promises not just quality but also an assurance that every cut is a step towards perfection.

If you’re looking to revolutionize your manufacturing process and want a machine that matches your ambitions, don’t hesitate to make an inquiry. We are here to guide and provide the best solutions tailored to your needs.contact us now!

Company Information

Dalian Jiuying Heavy Machine Co., Ltd. was established in 2015, focusing on sheet metal processing. At present, it mainly sells various metal cutting equipment, such as plasma cutting machine, laser cutting machine, water jet, etc. We have strong project design and product development capabilities, and can also provide customers with customized production services.

Cutting machines produced by Jiuying Heavy Machine Co., Ltd. are widely used all over the world with its advanced technology and high cost performance. Our customers are all over the world.Our international markets currently include the United States, Russia, the United Arab Emirates, the Philippines, Indonesia, Malaysia, Bangladesh, South Africa, etc.

Our company since its establishment, always adhere to the “customer first” principle, and will be unremitting spirit of innovation, leading professional technical strength, standard technology and standards, advanced manufacturing and testing technology and equipment, and continue to meet customer needs of production and manufacturing capacity.

Jiuying hopes to seek long-term win-win cooperation with you. Please choose us to work with you to create a better future!

Our Certificate