Product

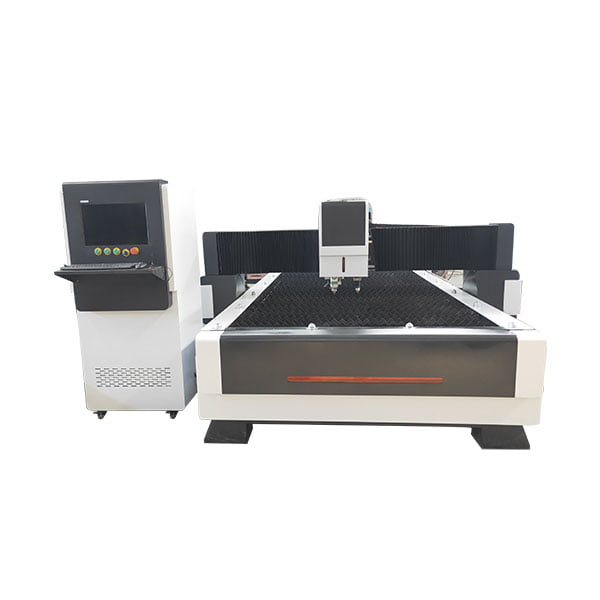

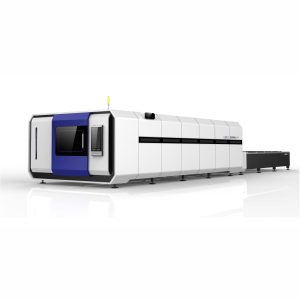

CNC Fiber Laser cutting machine

CNC Fiber Laser Cutting Machine

Main configuration:

1 Professional cypcut control system

2 EOE high precision servo motor 750W

3 high-precision square rail

4 Overall aggravating design

5 Heavy-duty body with exhaust duct

6 Industrial computer With a 19-inch screen, it is more in line with the habit of using a computer.

7 Swiss Raytool laser head with red light positioning operation is more stable and convenient

8 Chuangxin (The MAX1500W) laser

9 Planetary speed reducer

10 Hanli dual-cooling chiller is more professional and can work for a long time.

11 The new appearance design is more beautiful.

12 Pressure-resistant and explosion-proof water pipes and air pipes ensure the safe and stable operation of the machine under special circumstances.

13 1.25 film industrial rack.

14 Fully enclosed fireproof is a high and low temperature towline, which ensures the safety of the operation site.

15 X-axis flame retardant dust cover.

16 Schneider electronic components in France

17 Highly flexible, anti-breaking, cable that can shield external interference signals

18 Fully automatic oiling system

19 Easy-to-feed bull’s eye wheel

CNC Fiber Laser Cutting Machine Specification

|

Equipment Specification

|

|||||

|

Model

|

3015H

|

4015H

|

6015H

|

4020H

|

6020H

|

|

Cutting Area

|

3000*1500mm

|

4000*1500mm

|

6000*1500mm

|

4000*2000mm

|

6000*2000mm

|

|

Laser source

|

MAX

|

MAX

|

MAX

|

MAX

|

MAX

|

|

Max Moving Speed

|

100m/min,Acc=1.0G

|

100m/min,Acc=1.0G

|

100m/min,Acc=1.0G

|

100m/min,Acc=1.0G

|

100m/min,Acc=1.0G

|

|

Position Accuracy

|

±0.03mm

|

±0.03mm

|

±0.03mm

|

±0.03mm

|

±0.03mm

|

|

Reposition Accuracy

|

±0.02mm

|

±0.02mm

|

±0.02mm

|

±0.02mm

|

±0.02mm

|

|

Power

|

380V 50/60Hz 50A

|

380V 50/60Hz 50A

|

380V 50/60Hz 50A

|

380V 50/60Hz 50A

|

380V 50/60Hz 50A

|

|

Max Loading(KG)

|

≤4000

|

≤5000

|

≤5500

|

≤6000

|

≤6000

|

CNC Fiber Laser Cutting Machine Product Details

Professional cypcut control system

CypCut plate cutting software is a deep design for the fiber laser cutting industry. It simplifies complex CNC machine operations and integrates CAD, Nest and CAM modules into one. Drawing, nesting, and workpiece cutting can all be done by one person with just a few clicks.

High strength tube welding machine

It adopts 8mm high-strength steel pipe laser blanking, plug-in bed structure, adopts 3 welding processes, and the welding seam is not easy to tear.

Workbench

Sliders are installed on the edge of the platform, this design helps to load the board more and protects it from scratches. High stability knife table, reduce the contact between material and table. Serrated platforms and trim strips are ideal for cutting sheet metal, which reduces sparks flying during laser cutting. Five modular design, can be disassembled separately to save customer cost.

Applicable materials

Share:

Related products

Request a Quote

Ready to Work Together? Build a project with us!

Learn More From

Frequently Asked Questions

Please tell us what you want to mark, the size and desired power and other information.

Yes, we will, English manual and video will come along with the machine.You also can contact our service team if you need any help during use our machines.

Delivery time is 20-30 days after receiving the deposit

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

MOQ is one set, and warranty is one year.