Laser tube cutting machine maintenance is essential for both long-term efficiency and smooth operation. At Jiuying, we not only provide high-quality equipment but also offer expert support to ensure your machine performs at its best. Below, we’ll guide you through key maintenance tips for the cooling, optical path, and transmission systems. By following these guidelines consistently, you’ll minimize downtime, prevent costly repairs, and maximize productivity. When you’re ready for an upgrade or need assistance, we’re always here to help.

Cooling System Maintenance

To begin with, the cooling system is a crucial part of maintaining your machine’s performance. You should regularly replace the water in the cooler—whether it’s pure water, distilled water, or antifreeze—every 2-3 months. This step is important because the quality and temperature of the water directly impact the machine’s efficiency. By keeping the water below 38°C, you prevent scale from forming and blocking the system, which could lower cooling effectiveness.

Moreover, it’s essential to keep water flowing smoothly at all times. The cooling water removes heat generated by the laser tube, and any increase in temperature can reduce the machine’s power output. Therefore, regular checks for blockages, bent pipes, or pump malfunctions are critical. If performance issues or cooling problems arise, our service team is always available to provide replacement parts or repairs, ensuring that your machine operates at peak efficiency.

Optical Path System Maintenance

Another key area to focus on is the optical path system, as dust and debris tend to settle on lenses over time, affecting laser performance. Regular cleaning of these optical components helps ensure that your machine continues to deliver high-quality results. When wiping the lenses, use cotton wool dipped in ethanol, carefully wiping from the center outward to avoid scratching the surface.

Additionally, reducing high-speed perforations and opting for conventional methods whenever possible can help extend the lifespan of the lenses. At Jiuying, we offer customized maintenance solutions to keep your machine performing at its best. If you ever need assistance or advice, our team is always ready to help.

Transmission System Maintenance

Equally important is maintaining the transmission system. During the cutting process, smoke and dust accumulate on the guide rails and linear axes, which can cause increased wear and reduced precision over time. Therefore, it’s vital to regularly clean these components to maintain smooth movement. After cleaning, apply lubricating oil and butter to the guide rails and rack to protect against wear. Oiling the bearings also helps keep the machine operating with high accuracy and efficiency.

If you detect signs of wear or need help maintaining your transmission system, we’re here to support you. Our team can assist with advice, parts, or repairs to ensure that your machine continues to deliver accurate, high-quality cuts.

Working Environment and Additional Precautions

The environment in which your machine operates is another crucial factor in maintaining its performance. It’s important to keep the workshop dry and well-ventilated, with a temperature range of 4°C to 33°C. In addition, positioning the machine away from devices that generate electromagnetic interference or vibrations—such as large power generators or mixers—helps to avoid disruptions in cutting accuracy.

Moreover, operators should always monitor the machine for any unusual conditions. Addressing issues immediately helps prevent minor problems from escalating into major ones. Regular inspections and timely replacement of parts are essential for maintaining your machine’s optimal condition. We offer ongoing support, and our team is happy to provide any replacement parts to ensure smooth, uninterrupted operation.

Why Choose Us?

At Jiuying, we provide more than just equipment—we offer a partnership to help you succeed. By implementing these maintenance tips, you can significantly enhance your machine’s performance, reduce downtime, and extend its lifespan. Whether you need expert guidance, replacement parts, or an upgrade, we are always ready to provide the solutions you need.

Here’s why partnering with us is a smart decision:

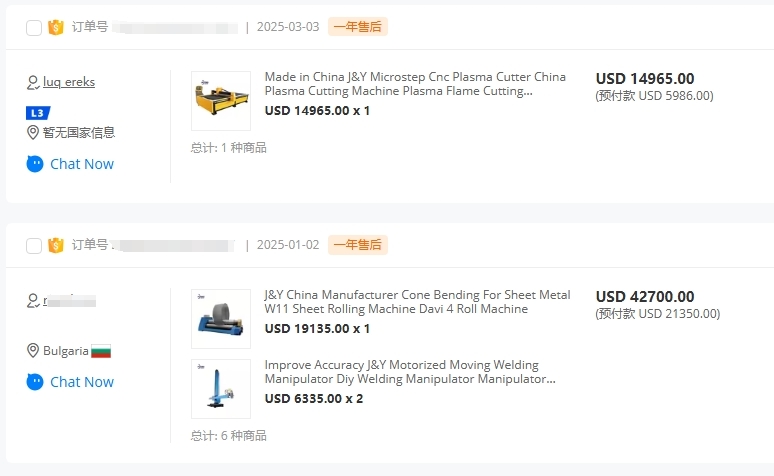

- One-year warranty on all laser tube cutting machines

- 24-hour online support to help resolve any issues

- Custom maintenance and upgrade packages designed specifically for your machine’s needs

Looking to boost your machine’s performance? Contact us today to place an order or learn more about our services. We’re excited to help your business grow with reliable solutions and unmatched support!