Introduction: Are you in the market for a cutting-edge solution that offers precision and efficiency? Dive deep into our Cantilever Water Jet Cutting Machine, a transformative product for all your intricate cutting needs. Let’s explore its features in detail:

Description:

Unveiling the next-gen Cantilever Water Jet Cutting Machine, a blend of robust design and precision. The central attraction, its split cantilever design, is backed by the durability of the Y-axis side frame crafted from welded concrete, ensuring unwavering stability. A testament to modern engineering, the X-axis, made from a one-time extruded 8mm aluminum alloy, strikes a balance between lightness and rigidity. Remarkably, this material choice slashes the weight in half compared to traditional counterparts.

For businesses that prioritize efficiency, our Cantilever Water Jet Cutting Machine’s spacious loading and unloading area proves invaluable. Strategically designed, this machine permits loading and unloading from three distinct sides, offering operational convenience. Its compact footprint ensures it fits snugly even in spaces where area is at a premium.

Cantilever Water Jet Cutting Machine Product Details:

- Melt Water Switch and Cutting Head: Featuring an innovative water switch with a novel structure that aligns with global design trends. Its frequently closed air cylinder and stable structure guarantee the concentricity of sand pipe and gems, ensuring longevity.

- CNC Servo Motor: Harnessing the prowess of Japan’s Yaskawa high-power servo motor, we assure unmatched stability and reliability during operations.

- Linear Guide Rail and Roller Screw: Precision is non-negotiable. The platform’s X, Y, and Z axes all employ top-tier Taiwan brands to eradicate stress and deformation, promising impeccable accuracy and steadfast stability.

- Water Trough and Grille Platform: Beauty meets functionality with a 5mm thick steel plate water tank. Additionally, the 100mm high grille bar is not only supportive but also designed for endurance, translating to fewer replacements.

- Y Axis Bed Base: Having undergone rigorous tempering failure treatment, the bed base is reinforced with concrete, enhancing its counterweight and stability during intricate tasks.

Cantilever Water Jet Cutting Machine Application fields

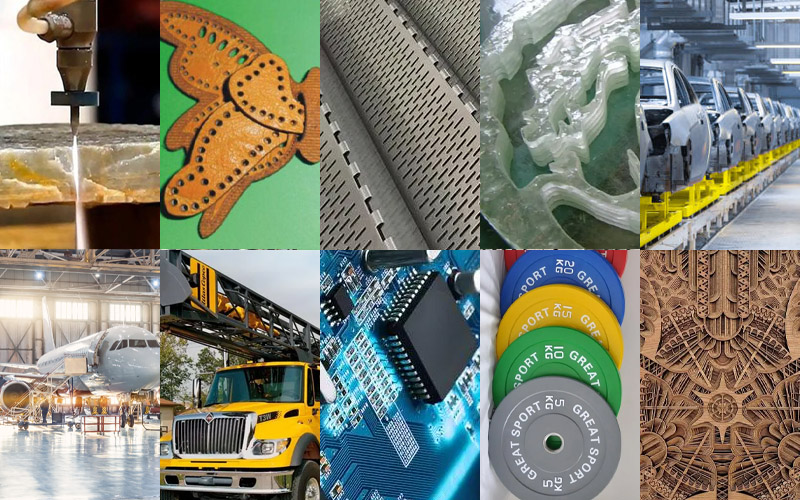

The Cantilever Water Jet Cutting Machine, given its precision and capabilities, finds its applications across a wide range of industries. Here are the primary application fields:

- Automotive Industry:

- Cutting and shaping car parts and components.

- Designing decorative elements and patterns for car interiors.

- Producing customized tools or equipment.

- Aerospace:

- Crafting intricate components for aircraft and spacecraft.

- Cutting specialized materials like titanium, alloys, and composites.

- Creating precise parts that meet strict aerospace standards.

- Electronics:

- Precisely cutting printed circuit boards (PCBs).

- Shaping casings, screens, and other electronic components.

- Designing and producing protective layers and films.

- Metal Fabrication:

- Cutting both ferrous and non-ferrous metals.

- Ensuring clean, burr-free edges on finished metal parts.

- Crafting ornate designs in metal sheets.

- Stone & Tile Industry:

- Shaping and designing intricate patterns on various stone materials, including marble, granite, and quartz.

- Crafting custom tiles for decorative purposes.

- Producing clean and precise cuts, reducing waste in expensive materials.

- Glass Industry:

- Providing precise and clean cuts for architectural and decorative glass pieces.

- Crafting customized glass components for various applications, including automotive and electronic uses.

- Textile Industry:

- Cutting fabrics, leathers, and other materials with high precision.

- Designing patterns and shapes for fashion and apparel.

- Rubber & Plastics:

- Shaping rubber components for industrial use.

- Crafting intricate designs in plastic sheets for various industries.

- Construction:

- Cutting and shaping materials for architectural designs, including metal panels, stone facades, and glass components.

- Art & Design:

- Creating sculptures, installations, and other art pieces from a wide range of materials.

- Crafting detailed patterns and designs for decorative purposes.

The versatility of the Cantilever Water Jet Cutting Machine, combined with its precision and efficiency, makes it a valuable asset across multiple industries, enhancing production capabilities and ensuring high-quality results.

Cantilever Water Jet Cutting Machine Product parameters

|

SPECIFICATIONS FOR WATER JET CUTTING MACHINE

|

|||

|

Max. pressure

|

420MPA

|

||

|

Max. flow rate

|

3.7L / min

|

||

|

Electrical source voltage

|

3 phases 220/380 Voltage, 50/60Hz, 37KW, 50HP |

||

|

Max. diameter of nozzle / orifice

|

1.02mm / 0.33mm

|

||

|

Max. delivery capacity of oil pump

|

106L / min

|

||

|

Max cutting heads

|

1-10 cutting heads (1 for standard machine)

|

||

Conclusion: Elevate your cutting processes with the Cantilever Water Jet Cutting Machine. Should you wish for more detailed information or a price quote, our team is always on standby. Don’t miss out on enhancing your operational efficiency; reach out to us today!