Advantages of Water jet cutting machine

No thermal deformation during waterjet cutting, avoiding physical and chemical changes of materials;

It is widely suitable for cutting and processing of various materials, and has the reputation of “universal cutting machine”;

The incision is smooth and flat without burrs, and generally no further processing is required;

The equipment is controlled by the numerical control system, and the cutting precision is high;

The cutting seam is less than 1.2mm, which is convenient for nesting cutting and saves materials;

The processing process will not produce waste that pollutes the environment;

CNC Water jet cutting machine is an ideal processing method for materials that are difficult to cut by other methods, such as aramid fiber, titanium alloy and various composite materials.

Water jet cutting machine is currently the cutting process with the most applicable materials;Cold cutting, no thermal effect, no secondary processing; can cut any straight line, curve, graphics, flexible and convenient;The slit width is only 1-1.5mm, the cutting surface is smooth and burr-free, and the roughness can reach 3.2μm-1.6μm;The workpiece does not need special clamping, and the operation is simple and convenient; the cutting range is wide, and the metal cutting thickness can reach 150mm.

High-precision and durable components

Chrome-plated guide rails and ball screws are used to effectively prevent wear caused by abrasives and corrosion. The ball screw and digital drive motion system ensure the high precision and long life of the waterjet

CNC console

The CNC console is fully upgraded, which is lighter, more beautiful, and more durable; external USB interface, file storage slot, convenient and flexible operation, and improved work efficiency; optional touch screen.

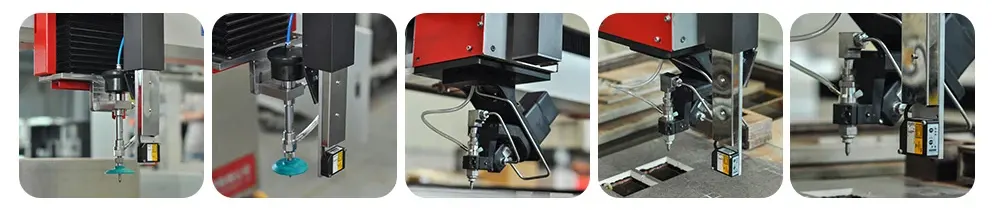

Multi-Head Cutting System

One device can carry multiple cutting heads. Improve production efficiency while reducing equipment input costs.

A variety of equipment options

Equipped with a CNC drilling device, it solves the problem of edge delamination caused by cutting interlayer materials directly for water cutting. The submerged cutting platform, the hydraulic system adjusts the water level, and the underwater cutting can effectively reduce noise and flying dust.

Automatic sand supply system

The sand supply tank is equipped with a sensor to monitor the remaining amount of abrasive. When the abrasive is almost used up, an alarm will be issued to remind the operator that it is necessary to refill. Adjustable abrasive feeding speed ensures continuous cutting, which really saves time and avoids waste.

Comprehensive upgrade of CNC system

The new control interface is more intuitive and easy to operate. Allows you to focus more on the production process and helps you intuitively translate drawings and cutting plans into final cut parts.

Waterjet Laser Scanning Altimeter

high efficiency

High-speed, dwell-free scanning and height measurement are achieved using a high-performance laser sensor with ms data sampling period.

high precision

High-precision sensors are used for data sampling, and the workpiece does not deform during the height measurement process. Laser measurement has high precision, which can be controlled within 0.05mm compared with the height measurement commonly used in the market.

high stability

Compared with the contact height measurement method, there is no risk of collision, the loss of hardware mechanism is low, and the service life is long.A variety of scanning schemes can be flexibly selected according to the shape of the cutting pattern to improve measurement efficiency.