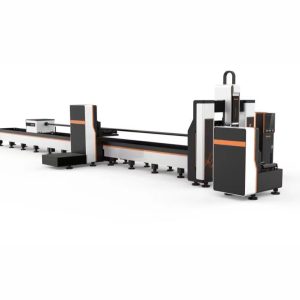

Fiber Laser Cutting Machine|High allocation Specification

A fiber laser cutting machine is a modern technological advancement in the realm of laser cutting, prized for its precision, efficiency, and versatility. Powered by a fiber laser, it uses amplified light that’s channeled through fiber optic cables to produce a laser beam used for cutting. Here’s a deeper dive into its features, advantages, and applications:

Technological Advantages:

- Precision Cutting: Powered by a focused laser beam, it ensures minimal deviations, resulting in highly accurate cuts.

- High Speed & Efficiency: Its fiber laser system delivers faster cutting speeds than conventional CO2 lasers, translating to increased production rates.

- Low Maintenance & Operational Costs: The absence of moving parts or mirrors in the light-generating source reduces maintenance requirements. Additionally, fiber lasers are more energy-efficient, which reduces operational costs.

- Versatility: Capable of cutting a diverse range of metals, including stainless steel, aluminum, brass, and more, with precision and ease.

- Durability & Longevity: Designed for a long operational life, reducing the need for replacements and ensuring a better ROI.

- Minimal Heat Damage: The high intensity and focused nature of the laser beam results in a smaller heat-affected zone (HAZ) compared to other cutting methods. This ensures better preservation of material properties post-cutting.

- Compact Design: Fiber lasers usually have a smaller footprint, which means they occupy less space, a crucial factor for facilities where space is at a premium.

- Advanced Control Systems: Modern fiber laser cutting machines come equipped with intuitive control systems, offering features like real-time monitoring, easy job setup, and automated optimization.

- Consistent Beam Quality: Fiber lasers produce a consistent and reliable laser beam, ensuring uniformity in cutting quality across jobs and over time.

- Safety: Given the enclosed beam delivery system, fiber lasers are deemed safer, minimizing the risks associated with open beams.

- Eco-Friendly: Consumes less power and, thus, has a lower carbon footprint compared to traditional lasers.

- Integration with Automation: Modern fiber laser systems can be seamlessly integrated with automation systems like robotic arms, allowing for faster and more efficient production cycles.

Features of the Fiber Laser Cutting Machine

The fiber laser cutting machine is the culmination of advanced technology, design, and functionality in the laser cutting industry. Let’s delve into its notable features:

- Contemporary Design:

- Open Structure: The machine boasts an open structure design, eliminating the need for covers. This not only provides an aesthetic appeal but also allows users to observe the entire cutting process in real-time, ensuring transparency in operations.

- High Processing Accuracy:

- Advanced Components: The machine is equipped with a high torque servo motor and an imported reducer of exceptional precision. This combination guarantees superior efficiency and dynamic performance, leading to precise cutting operations.

- Outstanding Dynamics & Cutting Ability:

- Robust Construction: The body of the machine is welded to ensure high rigidity. Paired with a gantry made of die-cast aviation aluminum, the overall structure provides an optimal balance of strength and lightness. This ensures exceptional stability, durability, and agility during operations.

- Ease of Operation & Intelligence:

- Custom Digital Control System: The machine incorporates a professional digital control system exclusively developed by Han’s Laser. This sophisticated system embodies the traits of excellent performance, high reliability, and user-friendly interface, ensuring seamless and intelligent operations.

- Cypcut Control System: A professional control system ensures smooth operation and precise control over cutting tasks.

- Economical Operations:

- Precision-Controlled Gas Consumption: One of the standout features is the machine’s ability to control gas consumption meticulously. This precision not only ensures the best cutting results but also translates to lower operational costs. Moreover, it offers flexibility to users by allowing them to select from three different types of auxiliary gases based on their preferences and requirements.

In summary, the fiber laser cutting machine, with its state-of-the-art design and functionalities, stands out as an industry-leading solution for businesses aiming for precision, efficiency, and cost-effectiveness in their cutting operations.

Advantages of the Fiber Laser Cutting Machine

Control System Features:

- Efficiency and Stability: The control system is rational, mature, and stable. It utilizes a central controller to manage the timing of switching equipment, safeguarding the longevity of crucial components.

- User-friendly Interface: The software interface is intuitively designed, compatible with a range of graphic data formats such as AI, DXF, PLT, and Gerber.

- High-Quality Components: Key electrical components in the control cabinet are sourced from renowned regions including Taiwan, Germany, and Japan, ensuring reliability and precision.

Han’s Fiber Laser Source Advantages:

- Innovation and Stability: The laser source boasts an innovative blend of optical fibers and avant-garde laser technologies, ensuring long-term stability.

- Industrial-grade Quality: Designed for the tough manufacturing environment, it stands out in terms of reliability and durability.

- Protection: Offers superior back-reflection protection, ensuring the safe processing of highly reflective materials.

- Efficiency: Achieves 43% photoelectric conversion efficiency, significantly reducing power consumption.

- Support: Equipped with remote diagnostic software for prompt and efficient support.

Cutting Head Advantages:

- Precision: Developed in-house by Han’s IR&D, the laser head has a focal length that reaches up to ±5mm.

- Dust Proof Design: Employs a proven sealed design to keep out dust and debris.

- Efficiency: The head is driven by a servo motor, ensuring rapid and efficient operation.

- Compatibility: The design is compatible with the mainstream QBH connector.

Advantages of Honeycomb Beam:

- Quality Assurance: Prior to machining, the honeycomb beam undergoes CAE Analysis and simulation to ensure the machine’s quality.

- Material Quality: Made from Q235 tensile strength mild steel, recognized for its superior quality in the industry.

- Stability and Reliability: The beam structure benefits from over 12 hours of heat treatment and advanced machining technology, ensuring long-term reliability.

Machine Bed Technology:

- Precision Machining: The bed is crafted using a Mitsubishi five-axis gantry precision machining master machine, imported from Japan. This guarantees the machine tool’s overall processing quality and the entire machine’s assembly precision.

- Dust Management: It employs a zoning dust ventilation system to manage dust produced during laser operations, ensuring an environmentally-friendly production process.

This comprehensive breakdown underlines the meticulous engineering and attention to detail that goes into every aspect of the Fiber Laser Cutting Machine, making it an indispensable tool in the realm of precision cutting.

Applications:

- Metal Fabrication: The machine’s ability to cut metals with high precision makes it invaluable in metalworking shops and industries, enabling them to craft parts, structures, and custom fabrications.

- Electronics: Used for precision cutting of circuit boards, electronic enclosures, and other components where intricate designs and tight tolerances are required.

- Medical Devices: Employed in the creation of surgical instruments, dental apparatus, orthopedic devices, and other medical equipment due to its precision and ability to work with a variety of metals.

- Aerospace & Automotive: Essential for cutting components used in aircraft and vehicles that require high precision, consistency, and quality. This includes engine parts, interior components, and specialized instruments.

- Jewelry: Leveraged for crafting intricate designs, engraving, and detailed metalwork, enabling jewelers to produce detailed and precise pieces.

- Energy: Used in the production of parts for the renewable energy sector, including solar panels and wind turbine components.

- Machinery and Equipment Manufacturing: Crafting parts for machinery in industries such as agriculture, construction, and mining.

- Shipbuilding: Cutting parts for ships, submarines, and other naval applications, especially those requiring precise tolerances and high-quality finishes.

- Textiles: While traditionally textiles are not the domain of laser cutters, fiber lasers can be used for precise cutting of tougher textiles or integrated materials and for engraving patterns on certain fabrics.

- Art and Sculpture: Artists utilize the precision of fiber lasers to create detailed metal art pieces, installations, and sculptures.

- Tools and Hardware: Used for designing and crafting tools, especially those that require intricate detailing or specific design needs.

- Signage and Trophies: For creating detailed metal signs, badges, and trophies, which require intricate detailing and sharp finishing.

- Home and Interior Design: Crafting decorative pieces, furniture elements, and other design components that are made of metal.

The applications of the Fiber Laser Cutting Machine are vast, and its versatility continues to open up new avenues and opportunities across various sectors. The machine’s ability to deliver precision cuts, combined with its efficiency and reliability, makes it an indispensable tool in modern manufacturing and design.

Fiber Laser Cutting Machine|High allocation Specification

|

Working area

|

12000*3000mm

|

|

x-axis travel

|

1520-3050mm

|

|

Y-axis travel

|

3020-12050mm

|

|

Z-axis travel

|

120-300mm

|

|

X.Y.Zaxis position accuracy

|

土0.05mm/m

|

|

Acceleration

|

1-2.5G

|

|

Maximum running speed

|

150m/min

|

|

Maximum table loading weight

|

7000kg

|

|

Laser power

|

12000W-30000w

|

|

Power supply

|

380V/50Hz

|

Conclusion:

The fiber laser cutting machine represents a significant leap in laser cutting technology. Its precision, speed, and energy efficiency make it a preferred choice for various industries. Whether it’s for intricate jewelry designs or large-scale industrial manufacturing, the fiber laser cutting machine delivers both precision and efficiency. If you’re considering laser cutting solutions for your business, a fiber laser cutting machine should definitely be on your radar.

Company Information

Dalian Jiuying Heavy Machine Co., Ltd. was established in 2015, focusing on sheet metal processing. At present, it mainly sells various metal cutting equipment, such as plasma cutting machine, laser cutting machine, water jet, etc. We have strong project design and product development capabilities, and can also provide customers with customized production services.

Cutting machines produced by Jiuying Heavy Machine Co., Ltd. are widely used all over the world with its advanced technology and high cost performance. Our customers are all over the world.Our international markets currently include the United States, Russia, the United Arab Emirates, the Philippines, Indonesia, Malaysia, Bangladesh, South Africa, etc.

Our company since its establishment, always adhere to the “customer first” principle, and will be unremitting spirit of innovation, leading professional technical strength, standard technology and standards, advanced manufacturing and testing technology and equipment, and continue to meet customer needs of production and manufacturing capacity.

Jiuying hopes to seek long-term win-win cooperation with you. Please choose us to work with you to create a better future!

Our Certificate