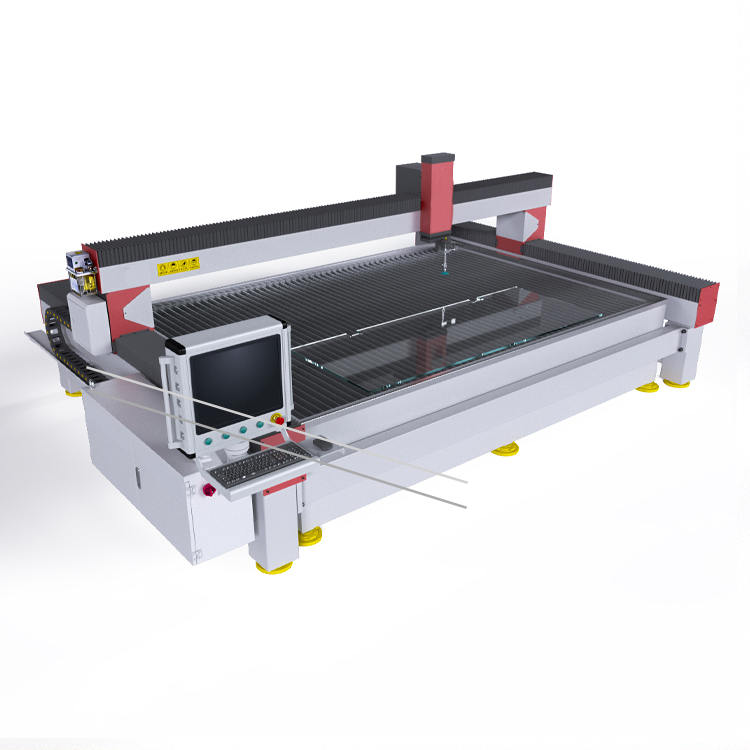

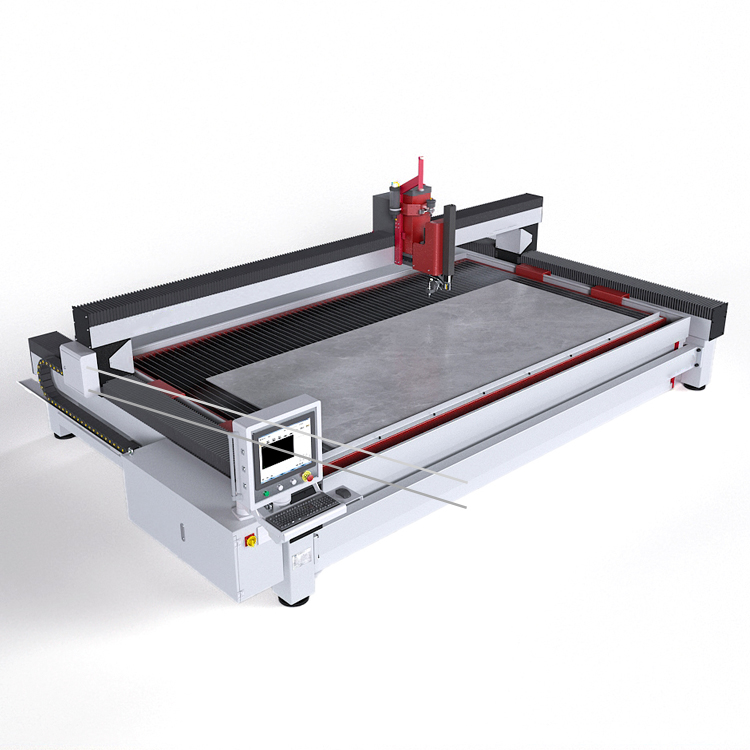

Gantry Water Jet Cutting Machine: A Comprehensive Introduction

Overview: The Gantry Water Jet Cutting Machine offers unmatched versatility for diverse cutting tasks. Designed to handle materials from metals, glass, stone, to composites, this machine stands as a testament to advanced cutting technology.

Key Features:

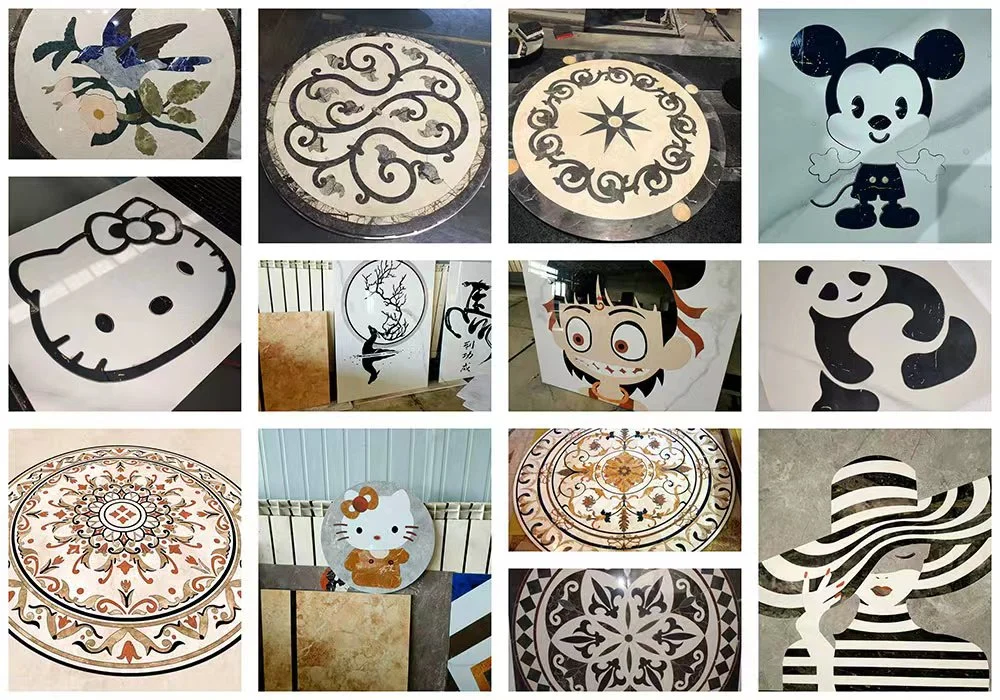

- Broad Material Versatility: Expertly crafted to accommodate a wide range of materials including metal, glass, stone, and composite materials.

- Cold Cutting Process: Thanks to its cold cutting approach, it prevents thermal effects, ensuring no need for post-cutting processes.

- Precision at its Best: Execute cuts from straight lines to intricate curves and designs. Enjoy a narrow slit width of 1-1.5mm for smooth, burr-free cuts. Achieve a surface finish with roughness between 3.2μm and 1.6μm.

- User-Centric Operation: A hassle-free experience with no special workpiece clamping required. Added mobility comes from the machine’s roller design, letting operators move and monitor with ease.

- Enhanced Cutting Depth: Capable of cutting metals up to a depth of 150mm.

Additional Highlights:

- Efficient User Interface: The expansive operation table ensures seamless interactions.

- Precision through Wireless Control: The machine is equipped with a wireless handle for precise knife settings.

- Adherence to European Standards: From electrical components to wiring, all align with European industrial norms.

- Automated Tool Adjustments: Enjoy the machine’s automatic tool compensation setting for effortless adjustments.

- Familiar Software Interface: The Windows-based system offers an intuitive user experience, ensuring ease of mastery.

- Path Visualization: Simulate cutting paths before actual operations for enhanced accuracy.

- Flexibility with Open System: Tailor the Gantry Water Jet Cutting Machine to specific needs with optional functional modules.

Structural Integrity:

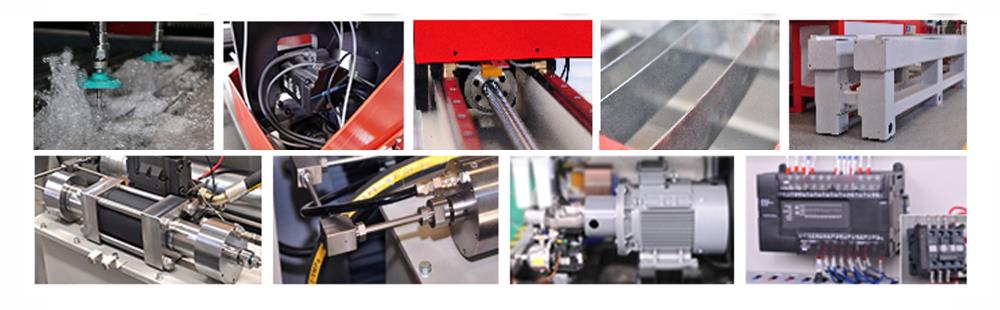

Maintaining precision and stability, the Gantry Water Jet Cutting Machine’s structure, especially the Y-axis, is fortified by casting beams and a base frame. The machine is notably annealed, significantly outperforming VSR treatments. The X and Y axes employ high-precision mechanics for impeccable cutting.

Specifications:

- Smooth finishes empowered by a 50 HP High 420 MPa pressure.

- Integral components like the “Intensifier” hail from the USA.

- Components processed using the renowned YASKAWA servo motor from Japan promise long-lasting performance.

- Y-axis components ensure unparalleled accuracy and durability.

- The machine boasts a comprehensive set including a cutting table, Intensifier Pump, CNC system, and a 5-AB axis water jet cutting head.

Product Showcase: Witness the capabilities of the Gantry Water Jet Cutting Machine through our cutting product display.

If the “Gantry water jet cutting machine” aligns with your requirements, don’t hesitate. For detailed insights, a bespoke consultation, or a competitive quote, our dedicated team is always at your service. Seize the opportunity to elevate your operations. Reach out today!