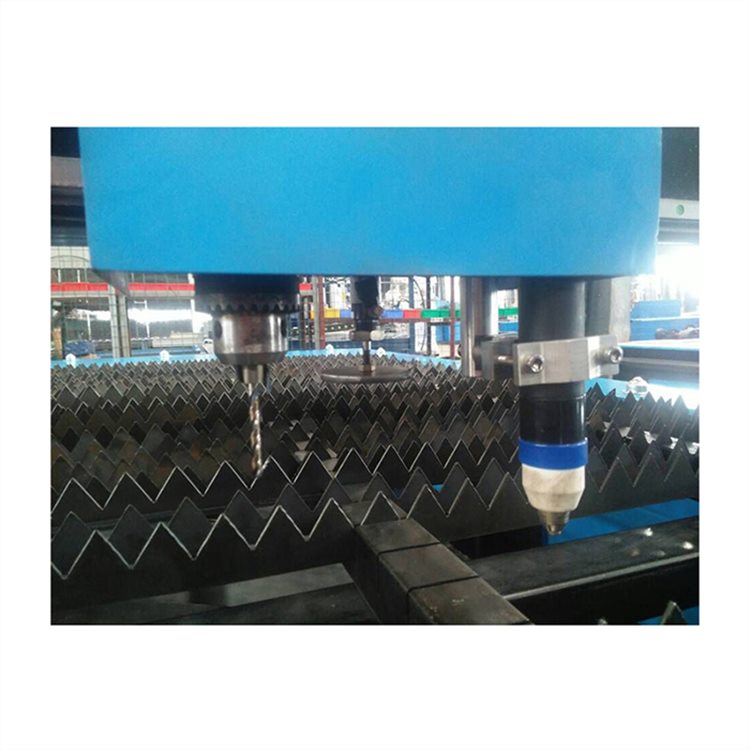

Desktop CNC drilling and cutting machine Product features:

1. Desktop CNC drilling and cutting machine is a set of computer control, precision mechanical transmission, thermal cutting in one of the high efficiency, high precision, high reliability of cutting equipment.

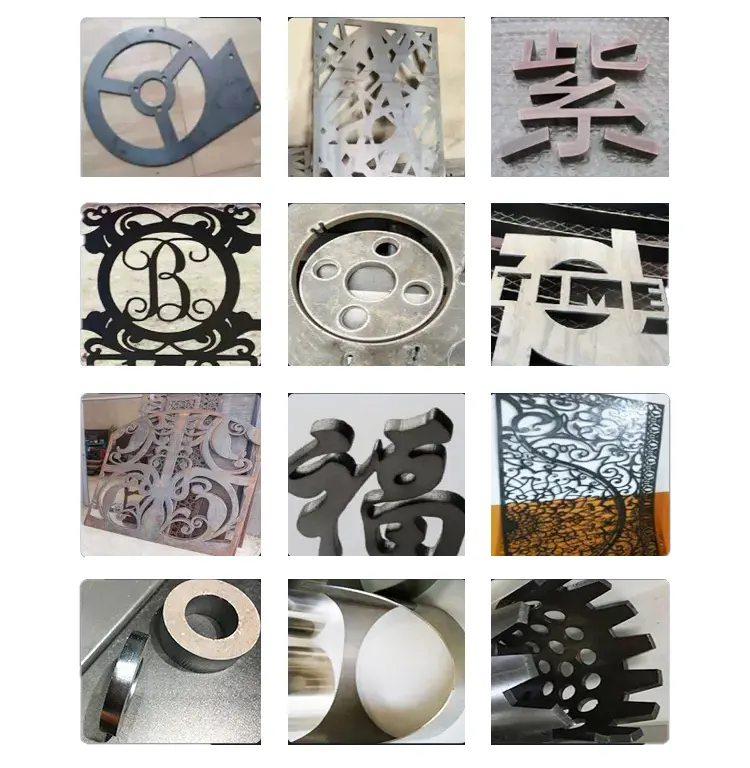

Good man-machine interface makes the operation more convenient and simple, can quickly and accurately cut out a variety of shapes of complex plate, especially suitable for medium and thin non-ferrous metal plate, stainless steel and carbon steel plate automatic blanking.

Adopt integrated modular design, fast installation, easy to move.

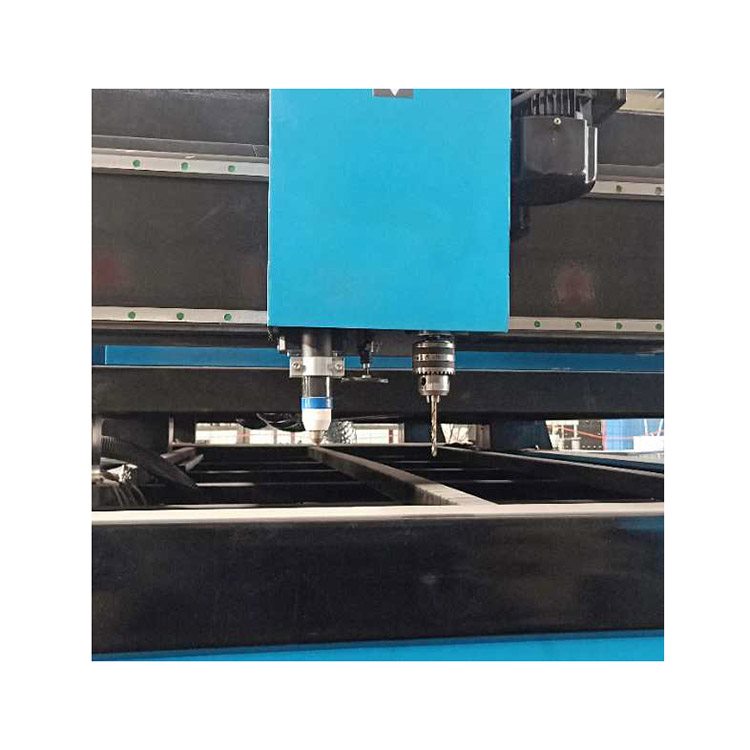

2. Both vertical and horizontal guides adopt domestic or imported linear guides with high precision and good guiding effect.

Longitudinal guide rail adopts special guide rail, surface grinding external, high mechanical precision, good wear resistance.

The transmission rack and pinion are customized by professional manufacturers.

Transverse and longitudinal transmission adopts Germany NEUGART or Japan high precision, high torque, low back backlash, maintenance-free planetary gear reducer.

3. Servo drive adopts Panasonic servo drive system, with position detection function, high motion accuracy, wide speed control range, short acceleration time.

4. Optional dust removal table or dust removal treatment device to create a good working environment.

5. A variety of plasma power supplies can be selected to meet the requirements of cutting different metal materials.

Desktop plasma CNC drilling and cutting machine is an efficient and precise plasma cutting machine. The integrated structure makes installation convenient, fast speed, small inertia and stable operation.

Especially suitable for the cutting of thin plate, can be designed as a smoking table according to user requirements, in order to meet the requirements of environmental protection.

Desktop plasma CNC drilling and cutting machine is designed for cutting all kinds of sheet metal parts in the company’s comprehensive consumer market. This machine cutting speed, surface cutting quality is good, and can be equipped with smoking treatment device.

The cutting speed can reach 10000mm/min.

Desktop plasma CNC drilling and cutting machine features

1. Longitudinal use of bilateral synchronous transmission system, longitudinal use of linear guide rail, so that the transmission is more stable, higher running accuracy.

2. The beam adopts light structure design. Good structural stiffness, light weight, small inertia.

3. With smoke exhaust treatment device, the machine structure is strict.

4. Suitable for all kinds of sheet metal, complex graphics proofing, as well as mass production, save complex punch mold, save proofing time, reduce cost.

5. Fast running speed, cutting speed up to 10 meters/min, suitable for batch processing, comparable with laser processing speed.

6. Low cost, is 1/10 of the cost of laser.

7. Easy to use, easy to operate, CAD graphics can be cut directly into the code.

Cutting product display

Product parameter

| Model | 2040 | 2060 | 2080 | 2560 | 3060 | 3080 | 30100 | 30120 |

| Effective cutting width (mm) | 2000 | 2000 | 2000 | 2500 | 3000 | 3000 | 3000 | 3000 |

| Effective cut length (mm) | 4000 | 6000 | 8000 | 6000 | 6000 | 8000 | 10000 | 12000 |

| Standard cutting torch number (set) | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| track length (m) | 4、6、8、10、12…… Track: 2 m/section, optional length of track | |||||||

| Cutting torch journey (mm) | 150 | |||||||

| Cuttingthickness (mm) | Flame cutting:5 – 200 mm Plasma cutting:1 – 50 mm (according to plasma size) | |||||||

| Cuttingspeed (mm/min) | Flame cutting:0 – 1000 mm/min Plasma cutting:0 – 5000 mm/min | |||||||

| Idle speed (mm/min) | 0 – 6000 mm/min | |||||||

| Power source | AC220 V/ 380 V 50HZ | |||||||

| Drive method | Bilateral drive | |||||||

| Machine drive motor power | 800 W/ 2500W | |||||||

| Cuttingmode | Flame cutting: oxygen + acetylene, propane plasma cutting: compressed air, oxygen, nitrogen, etc | |||||||