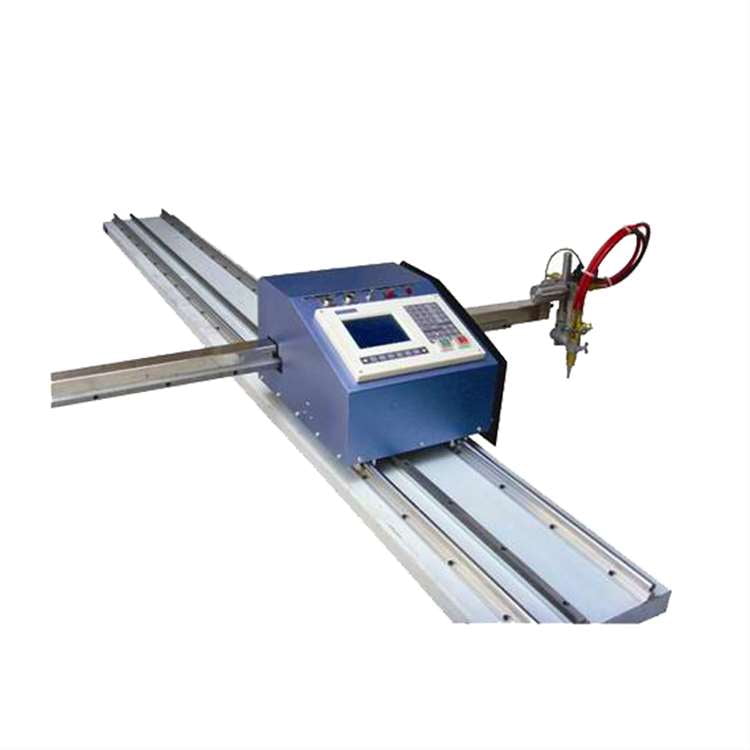

Portable CNC plasma cutter is one of the lightest and most economical CNC cutting machines available and is an alternative to imitation cutting machines. A portable cutter is a portable mechanical device used to cut a variety of metal materials, usually small and portable, for field or outdoor work.

Portable CNC Plasma Cutter: Main Features

1. Wide Industry Application:

- The Portable CNC plasma cutter finds its application in a plethora of industries including machine tool manufacturing, petrochemicals, light industry machinery, shipbuilding, aerospace, steel structures, and many more. Its versatility makes it the go-to equipment for sectors like shipbuilding, pressure vessels, and even aerospace.

2. Premium Hardware:

- The equipment is powered by a top-notch industrial computer imported from the USA. This ensures its reliability and efficiency in operations across various domains.

3. Compact & Mobile Design:

- It’s designed keeping in mind the needs of the modern industry. With a compact structure and a lightweight build, this device is both portable and easy to use, indoors or outdoors. It’s especially in demand in industries like locomotives, automobiles, and shipbuilding.

4. Efficient & Cost-Effective:

- Not only does it perform the tasks of traditional semi-automatic cutting equipment, but it can also cut intricate shapes just like large CNC equipment. This dual functionality boosts work efficiency, optimizes plate utilization, and reduces production costs.

5. Flexible File Transfer:

- The cutter supports multiple interfaces like USB (highly recommended) and RS232. Simply copy the auto-generated program file to a USB drive and plug it into the machine’s interface. This ease of transfer ensures hassle-free operations.

6. Graphic Tracking:

- The cutter stands out with its graphic tracking capability. It displays graphics in real-time during the cutting process, offering a more intuitive view of the ongoing task. It also supports functionalities like pausing, forwarding, rewinding, and speed adjustments during operations.

7. Advanced CNC Technology:

- Boasting cutting-edge computer numerical control technology, the machine eliminates manual programming. Instead, it uses programming software (provided complimentary) to automate the process. After setting up the AUTOCAD drawing and selecting the right programming parameters, the system directly generates a recognizable program (G-code file). This user-friendly approach not only reduces the manual input burden but also ensures that the equipment is easily accessible to all.

In essence, the Portable CNC Plasma Cutter is the embodiment of efficiency, precision, and user-friendliness, making it an invaluable asset for a vast array of industries.

Desktop CNC Plasma/Flame Cutting Machine: Product Details

1. Aluminum Structure Guide and Rail:

- Balanced Design: Features a patented design focused on geometric balance.

- Durability: The heavy-weight ensures it remains unbent even after prolonged usage.

- Precision: Guarantees high movement precision and impeccable cutting accuracy.

2. Alloy Aluminum Structure Body:

- Robust Construction: Built for longevity, this machine is robust enough to work continuously for years.

- Focus on Hardware Strength: While electronic components can be replaced when damaged, the hardware’s strength ensures the machine remains operational without the need for replacements.

3. Advanced Bearing Rollers for Guiding:

- Roller Count: The machine is equipped with 8 large bearing rollers each for the X axis guide and the Y axis rail.

- Duo Ball Guiding Rails: Ensures smooth and efficient movement.

- Steady Movement: The rollers are designed to grip the rails tightly at different points, ensuring stability and precision in movement.

4. Control System – Fangling F2100B:

- Popularity: A renowned control system in China with an extensive graphic library.

- User-Friendly: It’s designed for ease of use and offers support for 19 languages including Chinese, English, Russian, and Spanish among others. Custom language options are also available upon buyer’s request.

5. Lifting Station:

- Function: Designed to adjust the cutting torch vertically.

- Components: Utilizes the efficient Leadshine stepper motor and ball screw for transformations, ensuring smooth and steady movements.

6. After-sales Service:

- Comprehensive Support: Customers are provided with installation videos, operational guidelines, troubleshooting videos, and user manuals.

- Always Available: 24/7 online customer support ensures that users’ concerns are addressed promptly.

- On-site Assistance: If required, engineers are available for servicing in the buyer’s country.

In conclusion, this machine embodies efficiency, precision, and durability, backed by a robust support system. Whether you’re an industry professional or a newcomer, it promises to deliver top-tier performance consistently.

Product Paramenters

|

No.

|

Items

|

Parameters

|

|

1

|

Machine Voltage

|

Singal phase220V,50HZ

|

|

Plasma power Voltage

|

Three Phase 380V,50HZ

|

|

|

2

|

Cutting mode

|

Plasma+Flame

|

|

3

|

Effective cutting range(mm)

|

1500mm×3000mm or customized

|

|

4

|

Cutting speed(mm/min)

|

50-3500mm/min

|

|

5

|

Plasma power

|

Huayuan LGK-120A/200A/300A

or Hyperthem 80A/105A/125A optional

|

|

6

|

Plasma cutting thickness

|

According to power source models

|

|

7

|

Moving precision

|

±0.2mm/m

|

|

8

|

Cutting system

|

Fangling F2100B

|

|

9

|

THC

|

Fangling F1620

|

|

10

|

Software

|

ProNest8(standard) or Starcam

|

|

11

|

Total weight(kg)

|

126KGS

|

|

12

|

Emergency stop

|

Yes

|

|

13

|

Working temperature

|

-5~45℃

|

|

14

|

Relative humidity

|

<95% No condensin

|

Incisable figure

Product Show

If you’re looking to revolutionize your manufacturing process and want a machine that matches your ambitions, don’t hesitate to make an inquiry. We are here to guide and provide the best solutions tailored to your needs.contact us now!

Portable CNC Plasma Cutter/Cutting Machine: Application Range

The Portable CNC plasma cutter is an innovation that marries the convenience of portability with the precision of CNC technology. Designed as a lightweight and cost-effective alternative, its application extends to a multitude of domains. Let’s delve deeper into its expansive application range:

1. On-site Construction and Repairs: Given its portability, it can easily be used at construction sites for quick modifications and repairs without the need to transport large metal pieces back and forth.

2. Metal Art and Sculptures: Artists and sculptors can benefit from its precision in crafting intricate designs, especially when working outdoors or in spaces without heavy machinery.

3. Automobile Repairs and Fabrication: Workshops can employ this cutter for detailed repair works or for fabricating specific automobile parts without requiring a larger setup.

4. Agriculture: For repairing or fabricating agricultural tools and machinery on the spot, especially in fields or remote locations.

5. HVAC Industry: Ductwork often requires on-the-spot modifications or installations. The portability of this cutter can simplify such tasks.

6. Small Workshops: Especially for those without the space or budget for larger CNC machines, the portable cutter can provide the advantages of CNC cutting without the typical space requirements.

7. Emergency Rescues: In situations where metal barriers need to be cut to rescue individuals, such as in vehicle rescues, its portability can be invaluable.

8. Military and Defense: For quick fabrications or repairs in the field or in remote locations without the need for transporting heavy machinery.

9. Shipbuilding and Repair: Given that shipyards are vast and ships themselves can be challenging to navigate, having a portable cutter can simplify tasks that require on-the-spot adjustments.

10. Field Maintenance: For industries with expansive field equipment, like oil and gas or mining, the portable cutter can facilitate immediate maintenance without the need to dismantle and transport equipment to a central workshop.

11. Custom Metalwork: For businesses that create custom metal pieces, from signage to furniture, the portable cutter provides flexibility in design and production.

12. Education and Training: Educational institutions teaching metalwork or CNC operations can benefit from its portability, especially when demonstrating in different locations or departments.

In essence, the Portable CNC Plasma Cutter is not just an economical alternative but also a versatile tool. Its design and functionality make it apt for varied applications, ranging from heavy industry to artisan crafts. It brings CNC precision to the fingertips of those working outside the confines of traditional workshops.

Company Information

Dalian Jiuying Heavy Machine Co., Ltd. was established in 2015, focusing on sheet metal processing. At present, it mainly sells various metal cutting equipment, such as plasma cutting machine, laser cutting machine, water jet, etc. We have strong project design and product development capabilities, and can also provide customers with customized production services.

Cutting machines produced by Jiuying Heavy Machine Co., Ltd. are widely used all over the world with its advanced technology and high cost performance. Our customers are all over the world.Our international markets currently include the United States, Russia, the United Arab Emirates, the Philippines, Indonesia, Malaysia, Bangladesh, South Africa, etc.

Our company since its establishment, always adhere to the “customer first” principle, and will be unremitting spirit of innovation, leading professional technical strength, standard technology and standards, advanced manufacturing and testing technology and equipment, and continue to meet customer needs of production and manufacturing capacity.

Jiuying hopes to seek long-term win-win cooperation with you. Please choose us to work with you to create a better future!

Our Certificate